The above parameters are only for reference. Optimized parameters are determined by drilling process and lithology of formations on site.

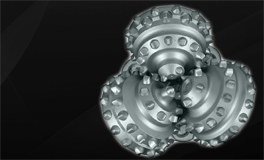

tricone bit nozzle and assembled size |

| Bit diameter | Nozzle outer diameter | assembled length | Nozzle exit diameter (inner diameter) |

| in | mm | mm | mm | mm |

| 3 1/2~5 1/2 | 88.9~139.7 | 20.3 | 17.5 | 4~10 |

| 5 5/8~7 3/8 | 142.9~187.3 | 23.6 | 19.0 | 5~16 |

| 7 1/2~8 1/4 | 190.5~209.6 | 29.8 | 21.0 | 7~18 |

| 8 3/8~14 5/8 | 212.7~371.5 | 33.0 | 27.0 | 8~20 |

| ≥14 3/4 | ≥374.6 | 40.9 | 27.0 | 10~22 |

| Note: the assembled lenght is length from nozzle inlet to retaining ring groove |

In China

In China high-quality wear-

high-quality wear- Value,Crafts,

Value,Crafts, Win-win cooperation

Win-win cooperation Platform business

Platform business